Ceramic

What's Ceramic?

A ceramic material is a sintered body produced by firing and heat-compacting an inorganic compound. Using our technologies we attained through production of high-purity sputtering targets, we have been producing sintered ceramics and ceramic powders with high purity and various compositions.

Ceramic powders

As materials for research-use in rechargeable batteries, we have been providing a variety of lithium-base complex oxides which are used for positive electrode materials, negative electrode materials or solid electrolytes.

Lithium complex oxides

※You can scroll and see

| positive electrode materials | LiCoO2、LiFeO2、Li2MnO3、 LiFePO4、LiCoPO4、LiMnPO4、 LiMn2O4、Li(NiMn)2O4、Li2NiPO4F |

|---|---|

| solid electrolytes | Li3BO3、Li3PO4、(LiLa)TiO3、Li2B4O7、 Li7La3Zr2O12、Li1.5Al0.5Ge1.5P3O12 |

| negative electrode materials | LiNbO3、Li2TiO3、Li4Ti5O12 |

LiCoPO

Lithium borate-base and lithium phosphate-base materials can be provided also in amorphous phase and in powder form.

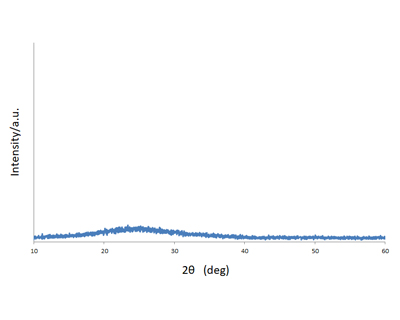

Li1.5Al0.5Ge1.5P3O12powders

amorphized Li1.5Al0.5Ge1.5P3O12

XRD spectrum of amorphous LAGP

Powders of magnetic materials

We have been producing various kinds of ferrite powders by synthesis technologies including solid-phase and liquid-phase reactions.

As we can produce customized powders, please ask us about it.

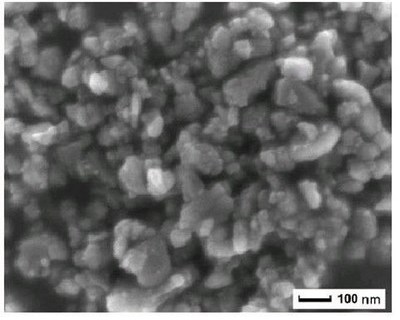

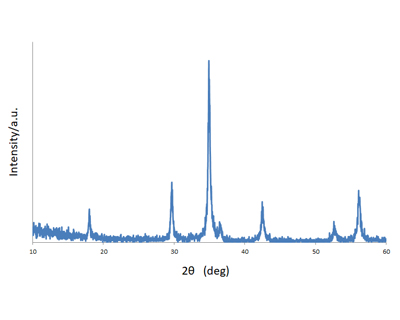

Example of analysis of MnFe2O4

SEMimage

X-ray diffraction

Fine Ceramics Sputtering Targets

Oxides

examples:MgO、 La2O3、 PZT、 PLZT、 STO、 AZO etc.

Carbides

examples:SiC、 B4C etc.

Complex targets

examples:Granular thin film materials: metal phases + non-metal phases called as “Cermet” in General.

metal phases = various pure metals and alloys, such as Fe, Co-Cr-Pt, Fe-Ni and Fe-Pt.

non-metal phases = various oxides and nitrides, such as SiO2,Al2O3 and MgO.

Other compounds

examples:nitrides,fluorides,sulfides

Besides the typical target materials described above, we can deal with a combination of various substances.

High-density SrRuOx target

Semiconductor memories employing SBT, KNN family and/or PZT family as a storage capacitor dielectric have been developed, and it is known that dielectric properties of the capacitor can be improved by using SrRuOx (SRO) for a bottom electrode in the capacitor, compared to using Pt. The use of SRO is expected also to reduce degradation due to reaction with the dielectrics during heating in the capacitor fabrication process, compared to the Pt case.

We have realized, by using our own technology, provision of a high-density SRO (SROHD) target which has a density of 90 % or higher and enables suppression of particle generation and stable thin film growth.