Core technology

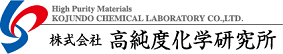

Melting Technology

We have been fabricating high quality alloys with only a very small amount of impurity by using five melting technologies including open-air melting, inert atmosphere melting, vacuum melting, arc melting and plasma melting.

Based on our knowledge and experience we gained for many years, we have been meeting needs of not only binary alloys into which two kinds of metals are mixed together but also special alloys such as ternary, quaternary and quinary ones, and further, highly active alloys.

Apparatuses we possess

- Small-size vacuum melting

- Large-size vacuum melting

- Open-Arc melting

- Plasma melting

- Inert-gas melting

- Open-Air melting and so on

Sintering Technology

We have been fabricating ceramics by five kinds of sintering technologies including open-air sintering, hot-pressed (HP) sintering, pressure sintering, spark plasma sintering (SPS) and hot isostatic pressing (HIP) sintering.

Further, as we have set up environments for synthesis and preparation of various kinds of powders, we can meet your needs of even special ceramics which have not been achieved yet in the world.

Apparatuses we possess

- Vacuum hot-press

- Quasi-Inert and/or Air Hot-press

- Spark plasma sintering(SPS)

- Air sintering

- Atmosphere pressure sintering

- Spray dryer

- Cold isostatic pressing (CIP) machine

- Molding machine and so on

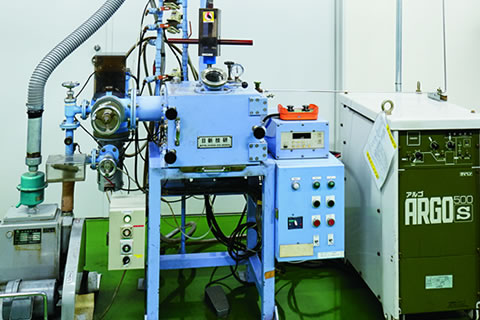

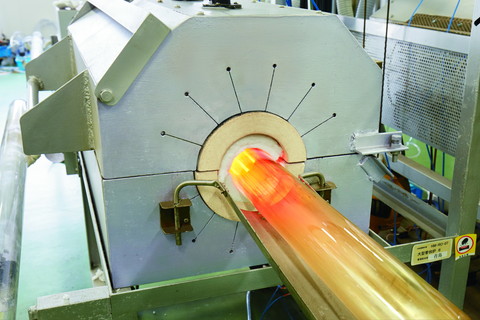

Mechanical Processing Technology

Equipped with a few tens of kinds of mechanical processing machine, including grinding machines, lathes, a wire electrical discharge machine and a slicing machine, we can perform processing of products into various dimensions and shapes, even when the products are made of special alloys or ceramics difficult to process using conventional processing technology or of highly active materials. Further, we can also deal with also plastic processing such as rolling and wire processing, wire cutting, pulverization, atomization and so on.

Apparatuses we possess

- Rotary grinding machine

- Plane grinding machine

- Cylindrical grinding machine

- Wire electrical discharge machine

- Slicing machines

- Lathe

- Milling machine

- Roller

- Stamp mill

- Brown crusher

- Ball mill

- Gas atomizer

- Planetary ball mill

- Fluidized-bed granulator dryer and so on

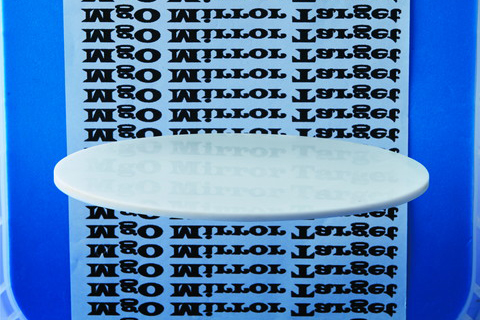

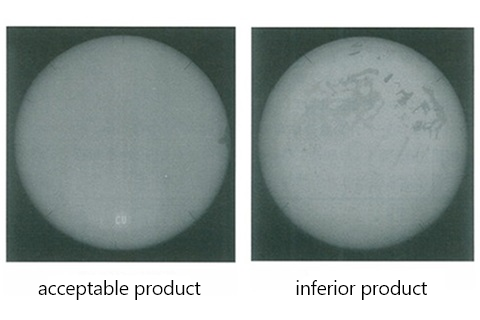

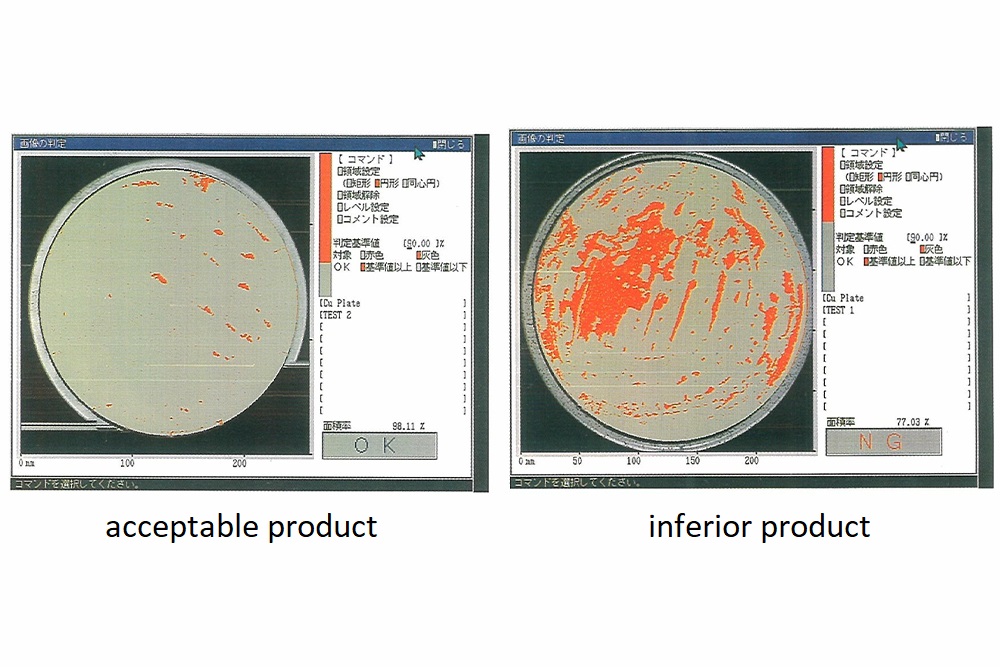

Bonding Technology

Based on abundant experience we gained as a manufacturer of sputtering targets, we will select a suitable bonding method for each material. Each and every bonded target is subjected to inspection to guarantee the quality.

Apparatuses we possess

- Bonder

- Ultrasonic flaw detection system

- X-ray inspection system and so on

Synthesis Technology

We have been synthesizing a variety of inorganic compounds including oxides, sulfides, phosphides, nitrides, halides and metal salts, and metalorganic compounds such as alkoxides and carboxylates. To be able to deal with highly active substances, metal powders, specified chemical substances and toxic substances, we are equipped with facilities for safe handling of powder materials, such as glove boxes and dust collection equipment, and have prepared environments enabling all material handling processes, including synthesis, pulverization and packing, to be performed under an inert atmosphere.

Apparatuses we possess

- Cylindrical electric furnace

- SiC based heater electric furnace

- Atmosphere furnace

- Wet reaction vessel

- Rotary kiln

- Vacuum glove box and so on

Distillation/Purification Technology

Our products developed on the basis of synthesis technology of metalorganic compounds such as alkoxides and technologies cultivated through our mass production of materials for silicon semiconductor devices have top-level quality in the industrial field.

For many years, we have provided semiconductor manufacturers with the products mentioned above which are of low particle and high quality. We have prepared a system to guarantee maintenance of a supply container such as a cylinder as well, and have been producing and developing products for a variety of uses from small scale production to mass production, including those of insulating layer formation materials, metal amide/imide compounds for ALD, high-k/ferroelectric materials and electrode formation materials.

Apparatuses we possess

- Distillation system made of SUS

- Sublimation system made of glass

- Distillation system made of glass

- Automatic packing system and so on

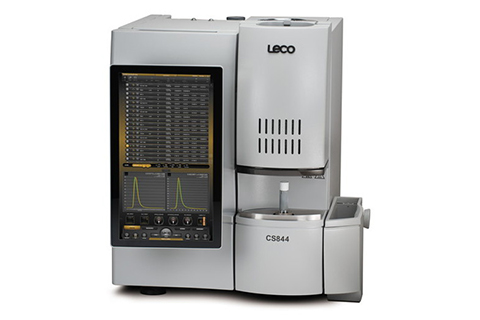

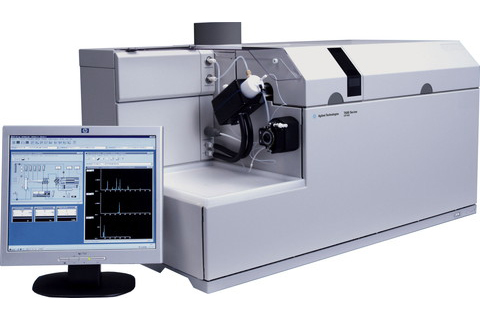

Analysis/Evaluation Technology

To guarantee quality of various kinds of products we provide, we have set up an analysis team dedicated to it and are equipped with state-of-the-art analysis instruments. In pre-processing of a sample prior to analysis, technologies we accumulated for many years as a manufacturer of high-purity materials are used. Analysis and evaluation we have been performing include quantitative analysis of a very small amount of metal element, oxygen/nitrogen gas content analysis, substance identification, surface analysis, foreign substance contamination analysis, material property analysis, and detection of internal abnormality or defects in a metal/alloy or sintered product.

Apparatuses we possess

- ICP-MS (Inductively Coupled Plasma Mass Spectrometer)

- ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometer)

- Oxygen / Nitrogen Analyzer

- Carbon / Sulfur Analyzer

- Particle Size Distribution Analyzer

- Atomic Absorption Spectrophotometer

- XRD (X-Ray Diffractometer)

- FE-SEM (Field Emission Scanning Electron Microscope)

- EDS (Energy Dispersive X-ray Spectrometer)

- AFM (Atomic Force Microscope)

- DSC (Differential Scanning Calorimeter)

- TMA (Thermomechanical Analyzer)

- TG-DTA (Thermogravimetry / Differential Thermal Analyzer)

- High Temperature Observation Microscope

- Infrared Moisture Meter

- Particle Counter and so on