- 高純度化学研究所

- ENGLISH

- Product Guide

- Materials for Thin Film Deposition

- Sputtering Targets

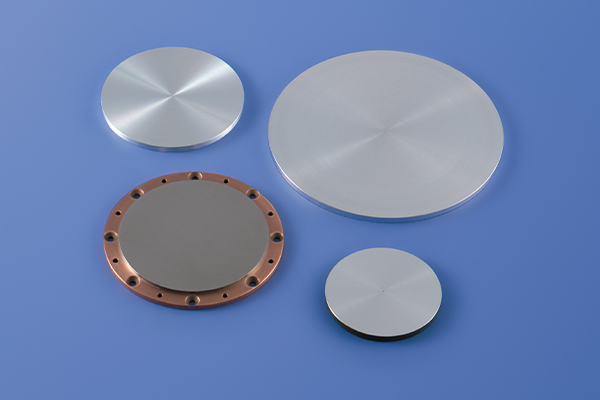

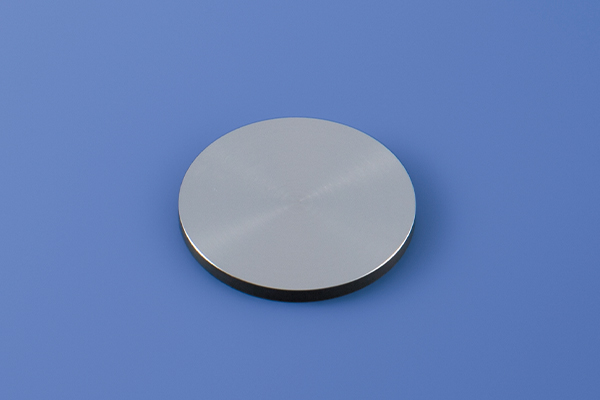

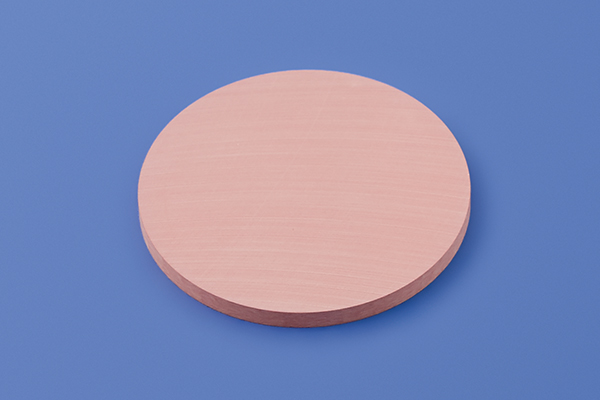

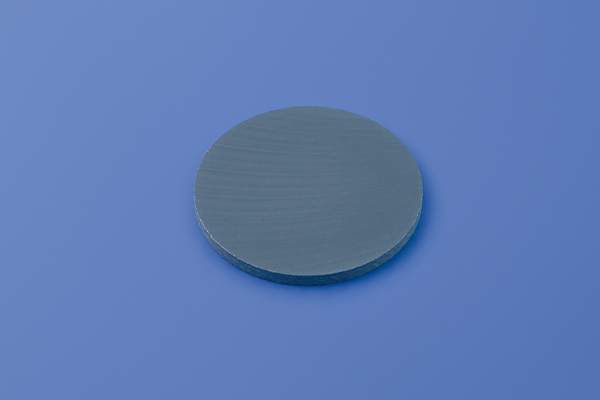

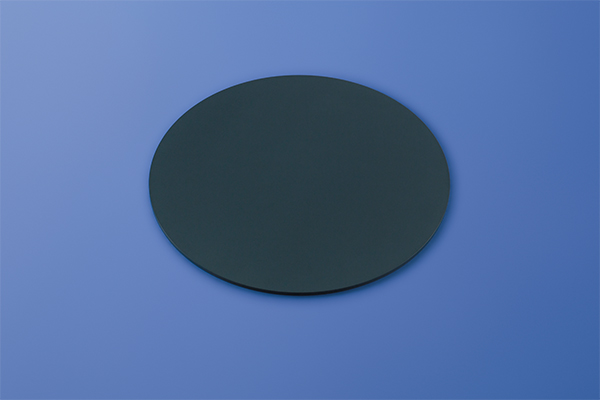

Sputtering Targets

Sputtering targets are materials from which thin films are grown by sputtering method, and the targets are fabricated by processing metals or ceramics. We have been providing sputtering target products of a variety of materials, purities and shapes, by combining our technologies of melting, sintering, synthesis and mechanical processing together. Selection of a fabrication method and customization according to the use and purpose are possible, and we will conduct fabrication of a target by an optimum fabrication method according to your request and a material of the target.

Further, we have been producing also backing plates used for the sputtering targets according to our customers’ requests.

Various links

Examples of sputtering target products in terms of material classes

Metal targets

※You can scroll to the side.

| High-purity metals | Al, Co, Cu, Fe, Mg, Mn, Sn |

|---|---|

| High melting-point alloys | Cr-, Mo-, Nb-, Ta-, Ti-, V-, W-based alloys |

| Non-magnetic alloys | Al-, Bi-, Cu-, Mg-, Sn-, Zn-based alloys/ Bi2Te3, Mg2Si |

| Magnetic alloys | Co-, Fe-, Ni-based alloys/ Co-Fe-B, Co-Pt, Fe-Pt |

| Heusler alloys | Various Co-, Fe- , Ni-based Heusler alloys |

| Mn-base alloys | Mn-Al, Mn-Bi, Mn-Ga, Mn-Ir, Mn-Si |

| Noble-metal alloys | Au-, Ag-, Pt-, Pd-based alloys |

Inorganic compound targets

※You can scroll to the side.

| Oxides | Al2O3,MgO,SiO2,TiO2,ZnO,La2O3 ITO,PZT,STO,LiCoO2,Li4Ti5O12,Li3PO4 |

|---|---|

| Carbides | SiC,B4C,WC |

| Other compounds | Nitrides, Fluorides, Phosphides, Sulfides, Selenides |

Complex targets

※You can scroll to the side.

| Metal phases | Various pure metals and alloys / Co-Cr-Pt, Fe, Fe-Ni, Fe-Pt , etc. |

|---|---|

| Non-metal phases | Various oxides and nitrides / Al2O3, MgO, SiO2, etc. |

Standard size table

※You can scroll to the side.

unit [mm]

| Circular | diameter | φ50.8、φ76.2、φ101.6、φ127、φ152.4、φ203.2、 φ254、φ304.8、φ355.6、φ406.4、φ508、φ533.4 |

|---|---|---|

| Rectangular | plane dimensions | 127×304.8、127×381、127×508、127×558.8、152.4×508 |

| thickness | t3、t5、t6.35 | |

Various high-purity metal target products

※You can scroll to the side.

| Al | ~6N | Mn | ~4N |

| Co | ~4N5 | Sn | ~5N |

| Cu | ~6N | Ti | ~5N |

| In | ~5N | Zn | ~5N |

| Mg | ~4N5 | ||

High-purity Mg

Believing that “technology innovation originates from high-purity materials”, we have been conducting development and production of various high-purity materials.

We have established a technology for Mg purification and, using high-purity Mg obtained by the technology, we have been providing Mg sputtering targets.

| purity | 4N5 |

|---|---|

| size | φ50.8~φ164 |

※You can scroll to the side.

Example of analysis

unit: ppm

| Element | High-purity Mg | Normal Mg |

|---|---|---|

| Ca | ND※ | 10 |

| Cd | ND※ | ND※ |

| Cu | ND※ | 10 |

| Fe | ND※ | 40 |

| Mn | ND※ | 40 |

| Zn | 20 | 20 |

※less than detection limit

High-purity Mn

Because of its brittleness, Mn is a material difficult to process into a high-purity target.

By optimizing target fabrication conditions, we have realized a high-purity Mn target.

| purity | 4N |

|---|---|

| size | please consult with us |

※You can scroll to the side.

Example of analysis

unit: ppm

| Element | High-purity Mn 4N |

Normal Mn 2N8 |

|---|---|---|

| Ca | ND※ | ND※ |

| Cr | 20 | 130 |

| Fe | 30 | 1400 |

| Mg | ND※ | 70 |

| Si | ND※ | 10 |

※less than detection limit

Alloys Co-Fe-B

Because of its brittleness, Co-Fe-B is a material generally produced by a sintering process.

We have established a technology for obtaining low oxygen-content Co-Fe-B by a melting method, and also realized a high-purity target by our purification technology.

We can make customization such as of the Co-Fe-B composition ratio and adding a fourth element in a form of Co-Fe-B-α, according to our customers’ requests.

| purity | 4N |

|---|---|

| size | φ50.8~φ300 |

| B content | ≦ 20atm% |

| gas content | O < 70ppm N < 70ppm |

※You can scroll to the side.

Example of analysis

unit: ppm

| Element | High-purity Co-Fe-B 4N |

Normal Co-Fe-B 3N |

|---|---|---|

| Al | ND※ | ND※ |

| Cr | ND※ | 20 |

| Cu | 20 | 20 |

| Mn | ND※ | ND※ |

| Ni | ND※ | 150 |

| Si | 20 | 20 |

※less than detection limit

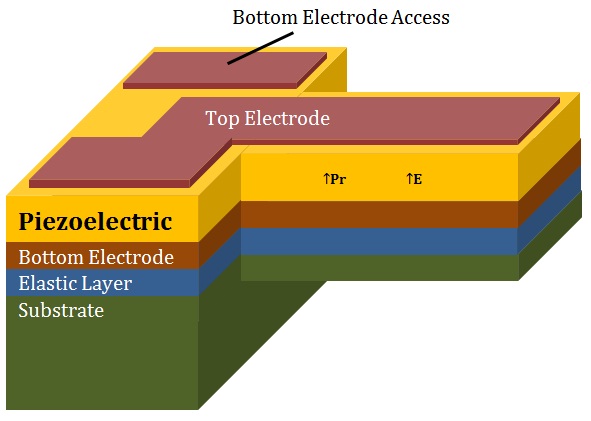

Examples of materials for MEMS

※You can scroll to the side.

| gate dielectrics | La2O3、HfO2、Y2O3、HfO2-Al2O3 |

|---|---|

| piezoelectric materials | PZT、PNZT、PLZT、PLT、PMN-PT、PNN-PZT、NaNbO3、KNbO3、KNN、BNT、BFO |

| high dielectric constant materilas | (BaSr)TiO3、SrTiO3 |

| electrodes | Pt、Ir、Ru、RuO2、SrRuO3、LaNiO3、(LaSr)CoO3、Ti、TiN、TiOx、Ta |

PZT target

PNZT (Nb-doped PZT) target

※You can scroll to the side.

| materilal | PZT | PNZT |

|---|---|---|

| available composition | PbaZrbTi1-bOx a=1.0~1.3 b=0.1~0.9 |

Pba(ZrbTi1-b)cNb1-cOx a=1.0~1.3 b=0.1~0.9 c=0.8~0.9 |

| size | φ50~ | |

| thickness | t3~t10 | |

| purity | 3N (excluding Hf 2000-3000ppm) | |

| impurities | Al、Cu、Ta<100ppm | |

High-density SrRuO3

SrRuOx(SRO)is a material used for a bottom electrode in a memory storage capacitor of DRAM and FRAM where BST and PZT are respectively used as the capacitor dielectics.

It is known that the use of SRO for the bottom electrode improves dielectic / ferroelectric properties of the capacitor, compared to the case of Pt electrode.

The use of SRO is expected also to reduce degradation due to reaction with the dielectrics during heating in the capacitor fabrication process, compared to the Pt case.

We have developed, by our own technology, high-density SRO (SRO-HD) which enables suppression of particle generation and stable thin film growth.

| purity | 3N(excludingZr) |

|---|---|

| size | up to φ300 mm |

| density (theoretical) | 85%(6.48[g/㎤])or higher |

Pb-free High dielectic constant / Piezoelectric Materials

We have been providing a wide range of Pb-free dielectric materials including high dielectric constant materials represented by (Ba,Sr)TiO3 and piezoelectric materials such as NaNbO3, KNbO3, (K,Na)NbO3 and BNT-BT.

(Ba0.5 Sr0.5) TiOxtarget

(BaSr)TiOx

Because of its high dielectric constant,(Ba,Sr)TiO3 has attracted attention in terms of its application as a capacitor dielectric of semiconductor memories. We have developed a target having lower resistivity than general, using our own technology.

| purity | 3N |

|---|---|

| size | φ50.8~φ300 |

| density | 90%or higher |

※You can scroll to the side.

| SrTiOx | (Ba0.5Sr0.5)TiOx | (Ba0.7Sr0.3)TiOx | (Ba0.8Sr0.2)TiOx | |

|---|---|---|---|---|

| or higher[g/㎤] | 5.12 | 5.63 | 5.68 | 5.84 |

| resistivity [Ω㎝] example value | 5×10-2or lower | 5×10-1or lower | ||

Examples of Rechargeable Battery Materials

※You can scroll to the side.

| positive electrode materials | LiCoO2、LiFeO2、Li2MnO3、LiFePO4、LiCoPO4、LiMnPO4、LiMn2O4、Li(NiMn)2O4 |

|---|---|

| solid electrolytes | Li3PO4、(LiLa)TiO3、Li2B4O7 |

| negative electrode materials | LiNbO3、Li2TiO3、Li4Ti5O12 |

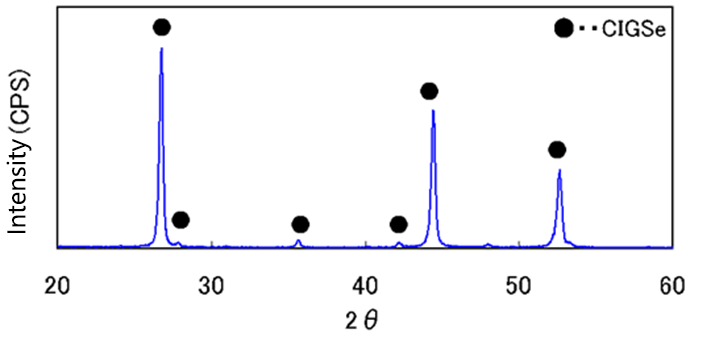

Examples of Solar Cell Materials

※You can scroll to the side .

| Anti-reflection coating | MgF2、SiN、TiO2、SiO2 |

|---|---|

| transparent electrode | GZO、ITO、IZO、TiO2-Nb |

| buffer layer | ZnO、ZnS、AZO |

| light-absorbing layer | CIS、CGS、CIGS、CAS、CZTS、S and/or Seide、Other composite materials |

| electrodes | Ag、Al、Mo |

for light absorption layer

Our own technology has enabled us to conduct optional composition control,

and we accordingly can provide powders or sputtering targets which have a composition in accordance with your request.

CuInxGa1-xSe2

| product | purity |

|---|---|

| In2Se3 | ~4N |

| GaSe | ~3N |

| CuInxGa1-xS2 | ~3N |

| CuInxGa1-xSe2 | ~3N |

| Cu-Ga | ~4N |

Rechargeable Battery Materials

We have been producing a variety of materials constituting rechargeable batteries, such as positive and negative electrode materials and electrolytes. We provide them in the form of a sputtering target, tablet or molded-sintered body, as thin-film lithium battery materials. Please consult with us about various shapes, combinations and customizations.

NbO

| product | purity |

|---|---|

| SnO2 | ~4N |

| NbOx | 3N |

| TiO2 | ~4N |

| MgF2 | 3N |

| ZnS | ~4N |

In2O3-SnO2

We provide targets and tablets for transparent electrodes and amorphous oxide semiconductors.

| product | purity |

|---|---|

| In2O3-SnO2 | ~4N |

| Al-doped ZnO | ~4N |

Al

| product | purity |

|---|---|

| Ag | ~4N |

| Al | ~5N |

| Mo | ~3N7 |

| ZnS | ~4N |

Examples of Materials for TMR/GMR Elements

※You can scroll to the side.

| magnetic layer | Co-Fe-B Co-Fe、Tb-Fe-Co、Ni-Fe、Ni-Fe-Co Co/Pt、Fe/Pt Mn-alloys as Mn-Ga Co-based Heusler alloys such as Co2(FeMn)Si |

|---|---|

| barrier layer | MgO、Mg |

| non-magnetic layer | Ag-alloys |

| spacer layer | Ru、Cu、Ta |

| anti-ferromagnetic layer | Ir-Mn、Pt-Mn |

| electrodes | Cr、Au、Ru、Ta |

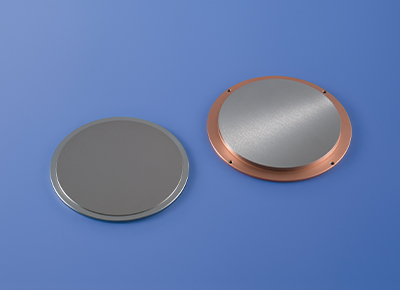

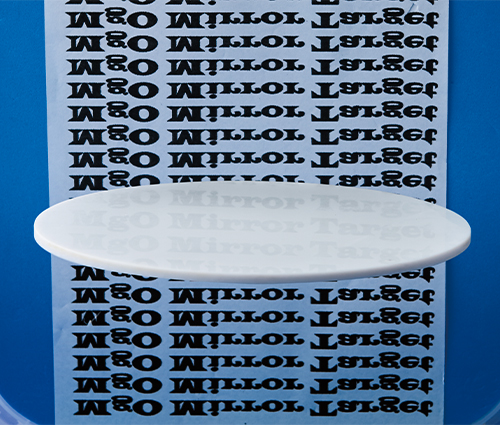

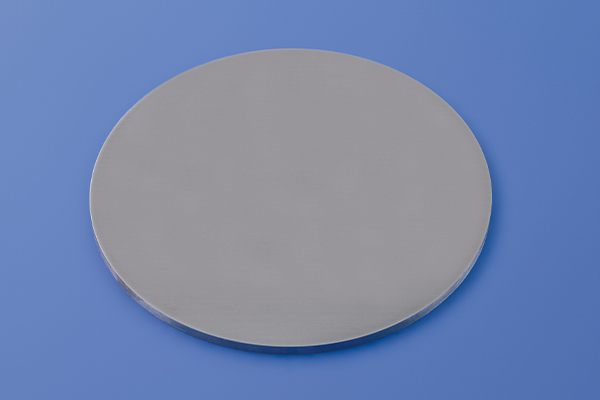

MgO

MgO is a functional material indispensable for a template layer and a TMR head of next generation HDD media and for magnetic devices such as an MRAM. We started development and production, in as early as 2002, of a sputtering target suitable for TMR elements, and have been providing MgO targets having features of “high purity”, “high density” and “low particle”.

Co alloys are materials used for various magnetic devices. We have provided Co-Fe-B targets and other various composition Co-alloy targets.

Examples: Co-Fe, Co-Fe-α, Co-Ni, Co-Zr-Nb, Co-Zr-Nb-Ta and so on

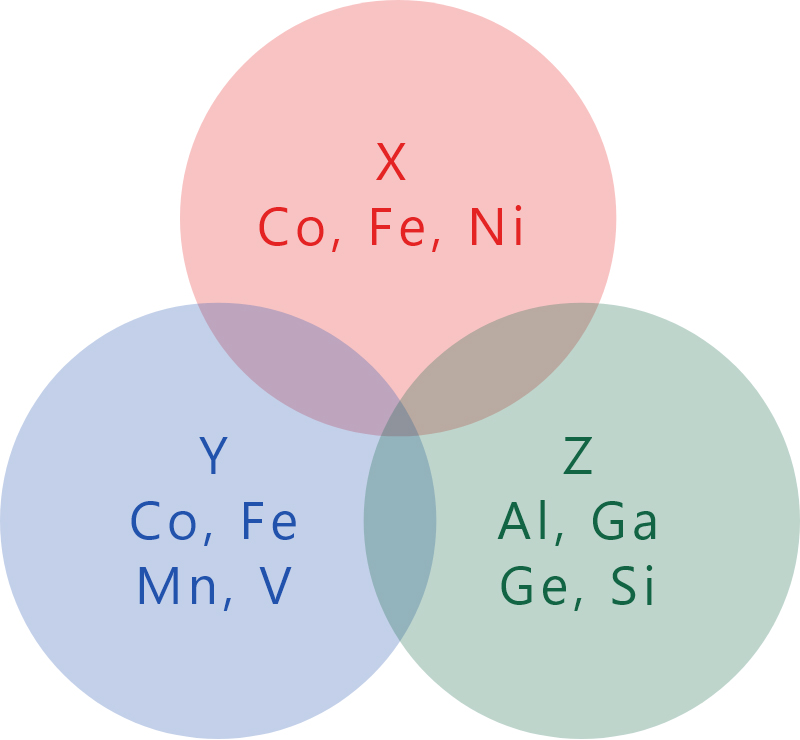

Co-base Full-Heusler Alloys by Melting

The full-Heusler alloys X2YZ are materials expected to be applied to magnetic devices such as MRAMs and magnetic sensors. While we have provided sintered targets, a range of their application has been limited by such as “deviation of thin film composition from target composition”. Further, there have been a lot of requests for low oxygen content products, because of the application to magnetic layers. The targets fabricated by melting are expected to resolve the problem associated with sintered targets.

Mn-alloys

We have been providing various kinds of Mn-alloy targets which are expected to be a new material for magnetic layers, by effectively using both sintering and melting processes. Most of Mn-alloys are brittle and, therefore, are produced by generally a sintering process. However, because of the application to magnetic layers, we have received a lot of requests for products with a specification of low oxygen content and for increasing the target size. Aiming at meeting such requests by providing a variety of targets fabricated by melting method, we have been continuing to tackle the challenge.

Mn-alloy:MnxGa100-x (55≦x≦75)

Of Mn-alloys having attracted attention recently as magnetic materials free of noble metals and rare earths, we can provide large-size targets fabricated by melting.

Low oxygen content Ir-Mn target by melting

Ir-Mn target

Ir-Mn is used for an anti-ferromagnetic layer in MRAMs whose primary features are non-volatility and infinite rewritable cycles. We have established a fabrication method of Ir-Mn targets by melting, and have realized low oxygen content in the targets. Compared with sintered targets generally used, the targets by melting can prevent influence of oxygen on other constituent layers.

- Gas content

O<150ppm、N<150ppm

- Purity

99.9%or higher(Fe<30ppm、Si<30ppm、Cu<20ppm)

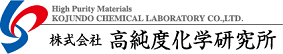

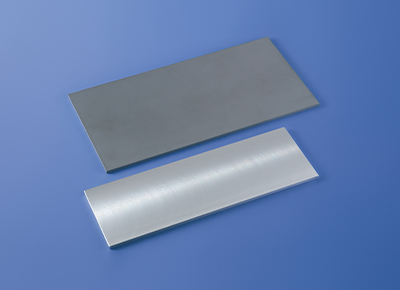

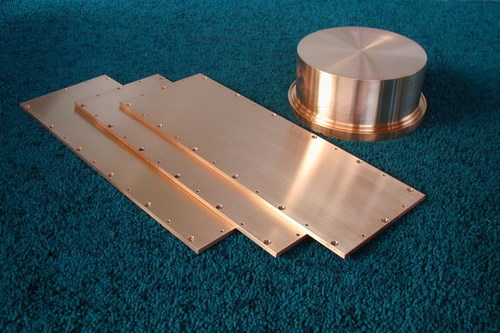

Based on technologies we have achieved regarding sputtering targets and their bonding for many years, we have enabled fabrication of backing plates meeting any request. For each of our backing plate products (a plate to which a sputtering target is to be bonded), we make careful selection of a material among various Cu-alloys including oxygen-free copper, steel, stainless steel, aluminum, Al-alloy, molybdenum and titanium, according to the customer’s use.

Further, we will also perfectly deal with also a combination of the above-mentioned materials and, considering ease of use for the customer, will also make suggestions for improvement.

Manufacturable Dimensions of large Backing plate

We can fabricate backing plates for sputtering targets ranging from a small one with a diameter of about 1 mm used for research and the like to a large one with a dimension beyond 2 meters used for the seventh generation large-size LCD. They can be fabricated in circular, rectangular or deformed shape. Even an order for fabricating one backing plate only is acceptable for us.

For inner-water-cooling type backing plates, we employ various bonding methods, such as blazing, electron beam welding and diffusion bonding, in accordance with the fabrication process. About material, shape, improvement and so on, please consult with us, at our sales department. In a case of initial fabrication of a backing plate, please provide us with the drawings or the target itself, as well as the spare backing plate. We will take the measurements and make drawings.