- 高純度化学研究所

- ENGLISH

- Product Guide

- Contract Services

- Production of Alloys

Production of Alloys

Melting Method

Melting is a technology used for producing an alloy, where metal materials such as aluminum and iron are melted together at a high temperature to yield their alloy. We have been fabricating high quality alloys with only a very small amount of impurity by using five melting technologies including air melting, atmosphere melting, vacuum melting, arc melting and plasma melting.

Based on our knowledge and experience we gained for many years, we have been meeting needs of not only binary alloys into which two kinds metals are mixed together but also special alloys such as ternary, quaternary and quinary ones.

We have melting technologies for treating high-purity materials of, mainly, nonferrous metals and alloys. Equipped with apparatuses for air melting and for atmosphere melting including vacuum melting, arc melting and plasma melting, we can produce multi-component alloys and, by forging and rolling, process them into desired shapes.

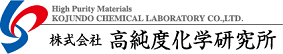

Melting process

In the melting process, we usually use raw metal materials with purities ranging from 99.9 to 99.999 %. A melting means to use is considered depending on the amount to melt and properties (melting point, activity) of the metals, and the melting process is performed under optimum conditions. If necessary, plastic working including forging and rolling is further performed.

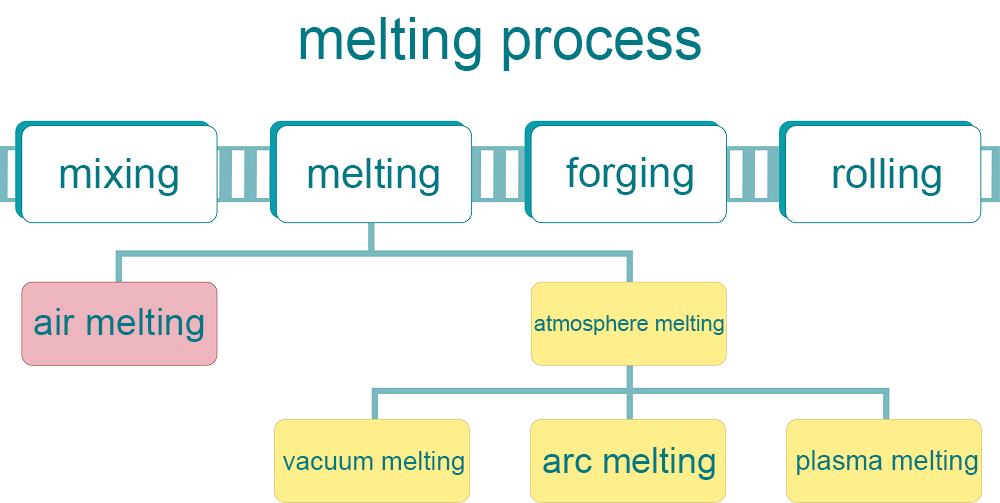

Vacuum Melting Furnace

large scale melting furnace

Melting of metals and alloys of a melting point up to 1700 ℃ is performed in vacuum. As electromagnetic induction heating is employed in the melting, melted metals are mixed well, and an alloy with uniform composition is obtained.

We are equipped with vacuum melting furnaces capable of processing 1 to 50 kg of materials (by converting to Fe), and thereby can meet our customers’ needs ranging from a small-amount spot product for R&D use to a large-amount product for a mass production line.

Having provided our customers with products in high quality, low price and short delivery time, we have gained the customers’ confidence.

Features of the vacuum melting furnace

- Metals are melted in vacuum using electromagnetic induction heating.

- Because of the induction heating, melted metals are mixed well to become uniform in composition.

- Because of the melting in vacuum, gas components in raw materials are removed and new oxidation is accordingly prevented. Further, incorporation of impurities can be prevented.

- Pouring the melted metals into a mold, an ingot or the like is fabricated.

Main products

- Fe-base alloy, Ni-base alloy, Co-base alloy, Al-base alloy, various materials for sputtering targets, special alloys (erg., Heusler alloy, Ir-Mn alloy)

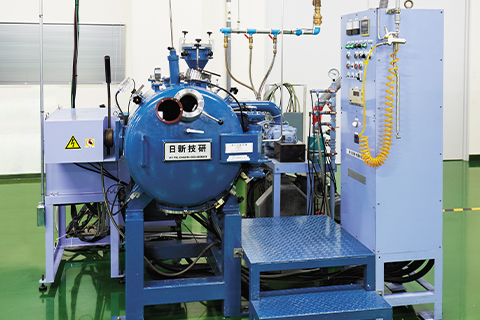

small scale melting furnace

Arc Melting Furnace

In an inert gas atmosphere, arc discharge is generated between a W (Tungsten) electrode (cathode) and a material embedded in a hearth (anode), and the material is melted by thus generated heat.

By the arc melting, it is possible to melt even high meting point or active metals/alloys which are impossible to melt by vacuum melting.

The melting can be performed on a material with a diameter of 50 to 200 mm.

Features of the arc melting furnace

- Active metals/alloys can be melted.

- In the melting, discharge is generated using a single Tungsten rod electrode when the material is small, and using a multiple number of rod electrodes when the material is large.

- Uniformity can be improved by conducting sample reversal and multi-cycle melting.

Main Products

- LaSi-base alloy, V-base alloy, Ti-base alloy etc.

Two-stage Roll Cold Roller

By passing a material to be rolled between rotating rolls, plastic processing of the material is performed into a desired thickness.

Thickness of a plate material is controlled by controlling a distance between the rolls during the passing.

related instruments

- Plasma melting furnace

- Internal pressure type melting furnace

- Inert gas melting furnace

- Open air melting furnace